Painting and Priming of a Swash Plate Assembly for Flight Safety

(Click on thumbnail to enlarge)

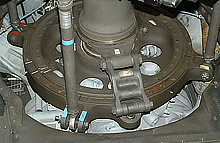

The swash plate assembly shown here is a device that translates input from helicopter flight controls into motion of the main rotor blades, and its function is essential to safe operation of the aircraft.

This integral flight safety assembly requires various processes prior to completion. To begin, the substrate is cleaned and tested for adhesion prior to masking. Applying sealant to the seams and inserted bushings is next. Primer application and topcoat are the final process of this job, making it one of the most intricate projects we do.

Quality control is essential with each step to ensure all flight safety requirements are met.

Priming & Painting of a Swash Plate Assembly – Project Information

- Capabilities Applied/Processes

- Priming (Polyurethane)

Painting (CARC)

Solvent Cleaning

Aerospace Sealant

Masking

- Overall Part Dimensions

- Diameter: 6'

Up to 500 lbs.

- Material Substrate

- Aluminum

- Finish

- MIL-PRF-85582 TY II Primer

MIL-DTL-53039D CARC

Color #37038

- In process testing/inspection performed

- Adhesion Testing

Thickness Testing

Visual Inspection

- Industry for Use

- Aerospace

Flight Safety

- Delivery/Turnaround Time

- Based on Customer Commitment Requirements

- Delivery Location

- Nationwide

- Standards Met

- All Flight Safety Requirements

- Product Name

- Swash Plate Assembly

Don't see the item you are looking for on this page? Please feel free to contact us for more information on our products & services.

Printable Page

Printable Page Email This Page

Email This Page